In its full service Chicago-based metrology laboratory, Gaspardo & Associates performs premium high accuracy computer aided measurement, inspection, verification, and reverse engineering services on near net shape and free form geometry component parts for a wide variety of industrial customers, including engineering firms, automotive and aerospace manufacturers and their tiered component suppliers, industrial mold and pattern producing manufacturers, injection molders and foundries, and stamping shops.

Capitalizing on cutting edge computerized metrological technologies, Gaspardo and Associates specializes in the exclusive use of three-dimensional optical measurement systems, state-of-the-art high-density point cloud digitization and modeling software, and customized 3D color map surface geometry reporting.

Coupling its modern measurement and output systems capabilities with innovative methodological advancements and techniques, Gaspardo and Associates leverages its superior overall process efficiencies in delivering unmatched value to its customers in the marketplace by increasing their product quality while measurably decreasing their time to market and therefore both developmental and manufacturing costs.

Gaspardo ComScan Automated

3D Scanning Solution

View Gaspardo ComScan Automated 3D Scanning Solution Brochure

| 3D Scanning / Digitizing Services | |

| Gaspardo & Associates applies its years of exclusive optical scanning expertise to quickly and accurately digitally capture and model the three-dimensional characteristics of virtually any object or component part of any material that fits within a four cubic foot envelope. | |

|

|

| Unlike traditional 2D manual or Coordinate Measurement Machine (CMM) methodologies, 3D scanning/digitizing uses light projection and reflection for the data capturing process, inherently providing measurable time and cost efficiencies over the existing legacy methods. | |

|

|

Particularly applicable for objects with high density geometries and/or free-form compound/curved surfaces, the process collects the high-accuracy 3D dimensional information in the form of a high-density data point cloud and assembles it in a virtual workspace. G&A’s state-of-the-art computer modeling software imports the 3D point cloud data for flexible and efficient utilization for a variety of purposes, including 3D CAD model generation, reverse engineering using all industry standard file formats, rapid prototyping, and computer-aided inspection/verification with emerging visual 3D color map surface geometry reporting. |

|

|

|

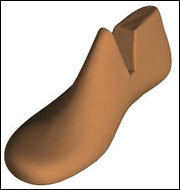

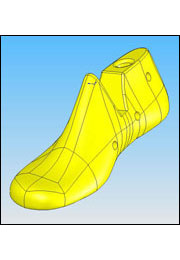

3D Reverse EngineeringImporting the point cloud data acquired through the 3D Scanning / Digitizing process into state-of-the art 3D computer modeling software, Gaspardo & Associates can efficiently Reverse Engineer items, components, or tools lacking sufficient original design documentation. |

|

|

|

| Outputs include fully-editable, high accuracy 3D virtual models for use in CAD/CAM/CAE software and industry standard design package formats for related re-engineering, rapid prototyping, and optimization processes employing modernized materials and manufacturing methods. | |

|

|

| G&A’s strengths in innovative methodological advancements and related techniques create measurable value for its customers, delivering time/cost-efficient customized Reverse Engineering solutions that facilitate increased product quality, improved enterprise communication and market evaluation, and decreased development costs and time to market from concept to end product. | |

|

|